Additive Manufacturing in Construction

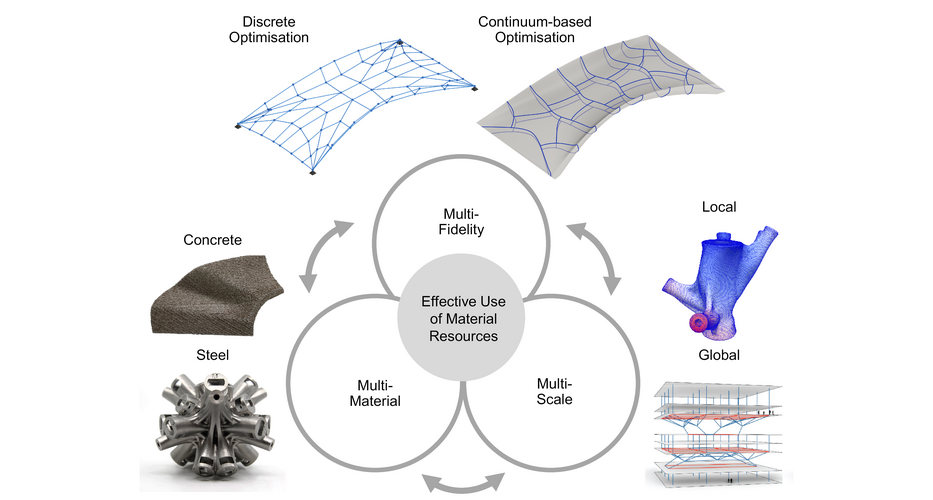

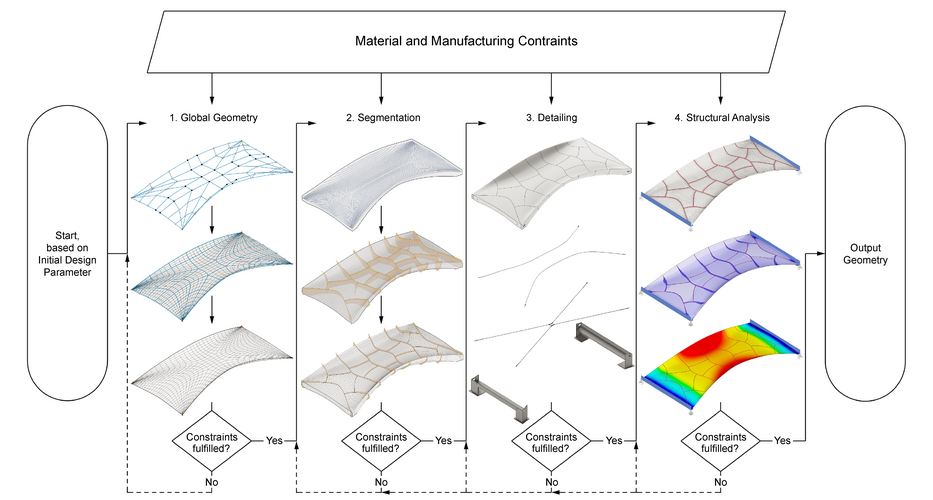

Traditional construction addresses architecture, engineering, and fabrication sequentially, leading to material overuse and inefficiency. The C02 Project: 3D Structural Puzzle tackles these challenges with its Holistic Design Framework (HDF), an innovative approach integrating advanced computational design, structural optimization, and additive manufacturing. By unifying these steps, the HDF facilitates resource-efficient designs that are both technically advanced and ecologically sustainable.

A central component of the HDF is the Discrete Optimization Approach (DOA), a method for conceptualizing structures grounded in graphic statics—a visual framework to evaluate how forces flow through a structure. This method enables designers to intuitively manipulate a structure’s shape and internal force distribution, leading to designs with exceptional structural performance. The DOA is both fast and adaptable, capable of accommodating various materials and connecting easily with more advanced optimization techniques.

A key milestone in the development of the HDF and DOA is the Bridge the Gap demonstrator, a compression-only, additively manufactured pedestrian bridge. Specifically, the project employed Selective Paste Intrusion (SPI), a powder-bed method for cementitious materials. This project highlights how the integration of DOA with advanced optimization and additive manufacturing can reduce material waste while ensuring structural integrity.

In summary, this research addresses inefficiencies in traditional construction and promotes sustainable practices, demonstrating how additive manufacturing can emerge as a viable, competitive solution for a greener, more cost-effective built environment.

Research Team:

Christiane Richter, Prof. Dr. Pierluigi D'Acunto, Professorship of Structural Design, School of Engineering & Design, Technical University Munich

Philipp Jakobs, Prof. Dr.-Ing. habil. Roland Wüchner, Professorship of Structural Design, School of Engineering & Design, Technical University Munich

Funding programme:

This research is supported by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) under project number 414265976 – TRR 277: Additive Manufacturing in Construction

Duration:

01.2024 - 12.2027

Related publications:

Schneider, Phillip, Dietrich, Sebastian, Richter, Christiane, Najian Asl, Reza, Straßer, Alexander, Kränkel, Thomas, Bletzinger, Kai-Uwe, Gehlen, Christoph, Kloft, Harald, D’Acunto, Pierluigi, & Dörfler, Kathrin: Fabrication-Aware Design Method and Experimental Assessment of a Segmented Concrete Pedestrian Bridge Using SPI Technology. In RILEM Bookseries (Vol. 53, pp. 362–369), 2024 more…